Manual Chokes

- Needle & Seat

- Gas Lift Choke

- Plug & Cage Choke

- External Sleeve Choke

- Anti Cavitation Concentric Cage Choke

- Velocity Control Choke

Automated Chokes

Pneumatic Actuator Operated

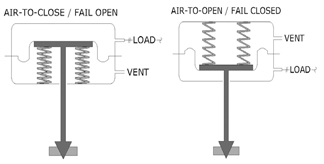

The most commonly applied actuator is the pneumatically driven actuator, because the power source – compressed air – is relatively cheap as compared to a human resource or electric or hydraulic power sources. From a maintenance point of view, pneumatic actuators are more easily service and calibrated than other types of actuator. Pneumatic actuators can generate substantial thrust to handle a majority of applications, including high-pressure and high-pressure-drop situations. Pneumatic actuators also bleed compressed air to atmosphere, which is environmentally safe, when compared to hydraulics. The main disadvantage of pneumatic actuators is that some response and stiffness are lost because of the compressibility of gases. Pneumatic actuators are available in two main forms; piston actuator and diaphragm actuator. They are available in single acting and double acting features. Smart positioner are available.

Features and Benefits:

- Quick-Disconnect feature – permits removal of actuator without depressurizing the valve. This greatly reduces downtime and lost production.

- Rising stem – provides visual indication of valve position.

- External safety relief device – protects the actuator from over pressurization.

- Compact design – permits easy maintenance in restricted areas.

JVS Flow Control LLC Mobile : (+1) 832 679 5266 Whatsapp : (+65) 9006 6046  Rohan Perera (rohan.perera@jvsengg.com)

Rohan Perera (rohan.perera@jvsengg.com)

Copyright 2012 JVS Flow Control. All rights reserved.

Copyright 2012 JVS Flow Control. All rights reserved.