Manual Chokes

- Needle & Seat

- Gas Lift Choke

- Plug & Cage Choke

- External Sleeve Choke

- Anti Cavitation Concentric Cage Choke

- Velocity Control Choke

Automated Chokes

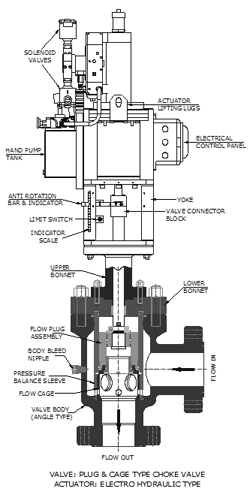

Electro Hydraulic Actuator Operated

Electro hydraulic valve actuators convert fluid pressure into motion in response to a signal. They use an outside power source and receive signals that measured in amperes, volts, or pressure. Choke valves can be moved to any position, including fully open or fully closed, within the stroke of the valve. Typically, valve actuators added to choke valves as part of a control loop that includes a sensing device and circuitry.

Important specifications for electro hydraulic valve actuators include actuation time and hydraulic fluid supply pressure range. Devices that move linear motion valves vary in terms of valve stem stroke length and actuator force or sealing thrust. For electro hydraulic valve actuators, acting type is an additional specification. With single-acting devices, fluid pressure actuates the valve in one direction while a compressed spring actuates the valve in the other. With double-acting devices, fluid pressure actuates the valve in both directions.

Features for electro hydraulic valve actuators include NEMA enclosures and actuator action. The National Electrical Manufacturers Association (NEMA), a non-profit trade organization, rates enclosures for electrical equipment. Devices with NEMA 4 and 4X ratings are suitable for indoor or outdoor use and provide protection against dirt, rain, sleet, and snow. For manual valve actuators, the actuator action can be direct (clockwise) or reverse (counterclockwise). Other features for electro hydraulic valve actuators include over torque protection, local position indication, and integral pushbuttons and controls. Travel stops or limit stops restrict linear or rotary motion. Manual overrides use hand wheels, levers, or hydraulic hand pumps for emergency operation.

JVS Flow Control LLC Mobile : (+1) 832 679 5266 Whatsapp : (+65) 9006 6046  Rohan Perera (rohan.perera@jvsengg.com)

Rohan Perera (rohan.perera@jvsengg.com)